CORTEX EBC

TAME YOUR TURBO WITH UNRIVALED BOOST CONTROL AT AN UNBEATABLE PRICE

The Cortex EBC is the best bang for the buck electronic boost controller available. An extremely flexible set of open-loop and closed-loop boost control parameters, combined with powerful configuration and data logging PC software, provides the Cortex EBC with the necessary tools to fine-tune every aspect of your boost curve.

Control turbocharger boost based on gear, RPM, vehicle speed, throttle position, ethanol content, or time. Optimize performance with launch- and spool-specific boost control functions. Protect your engine with a variety of fail-safe features. Save up to six unique boost control profiles to the controller and switch between them on the fly. Use two auxiliary PWM outputs to control water/methanol systems, nitrous systems, or even transbrake bumps. And with a starting price of just $350, you can do it all without breaking the bank.

KEY FEATURES

HIGH-PERFORMANCE BOOST CONTROL

Flexible Boost Control Strategies

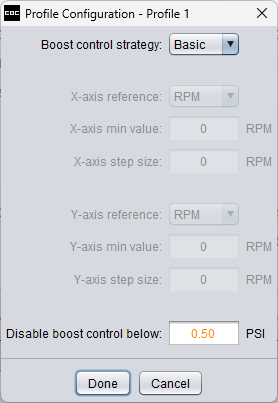

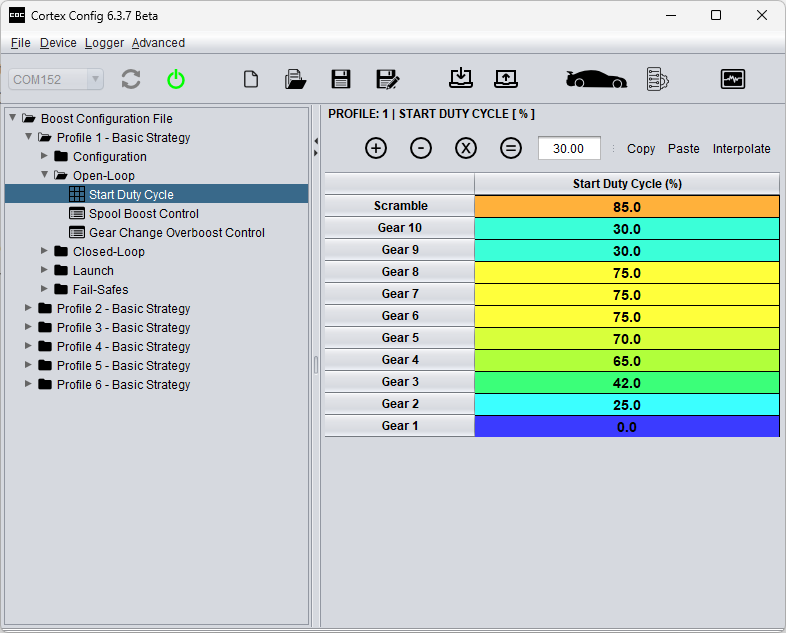

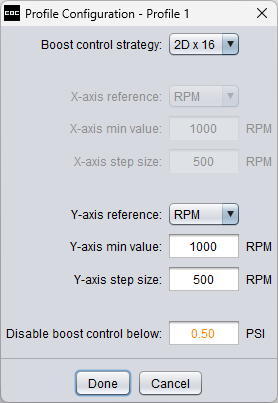

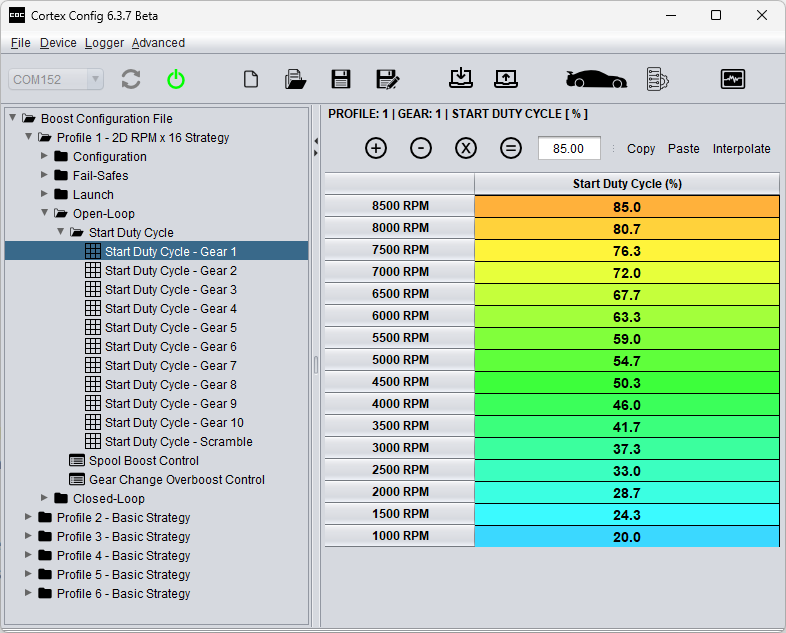

To maximize control flexibility, Cortex EBC boost configuration files include six fully independent boost control profiles, each configurable with a unique control strategy. From simple per-gear control to advanced multi-axis mapping, you can precisely match each profile to specific performance requirements—and switch between them instantly using the controller’s on-screen buttons.

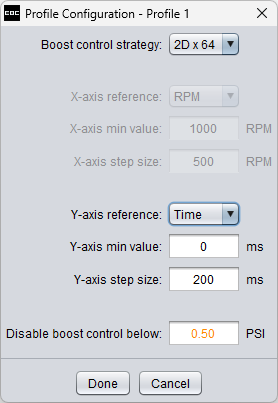

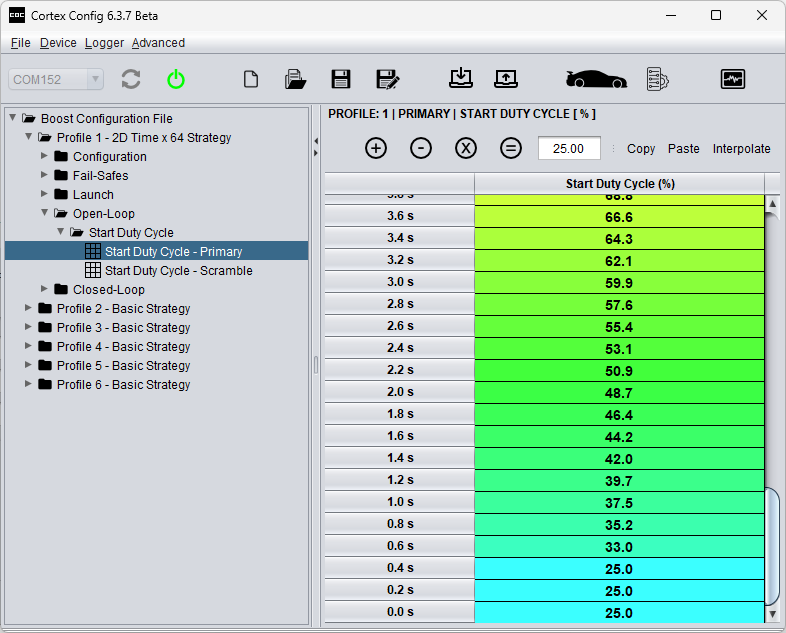

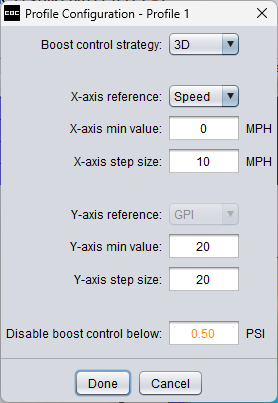

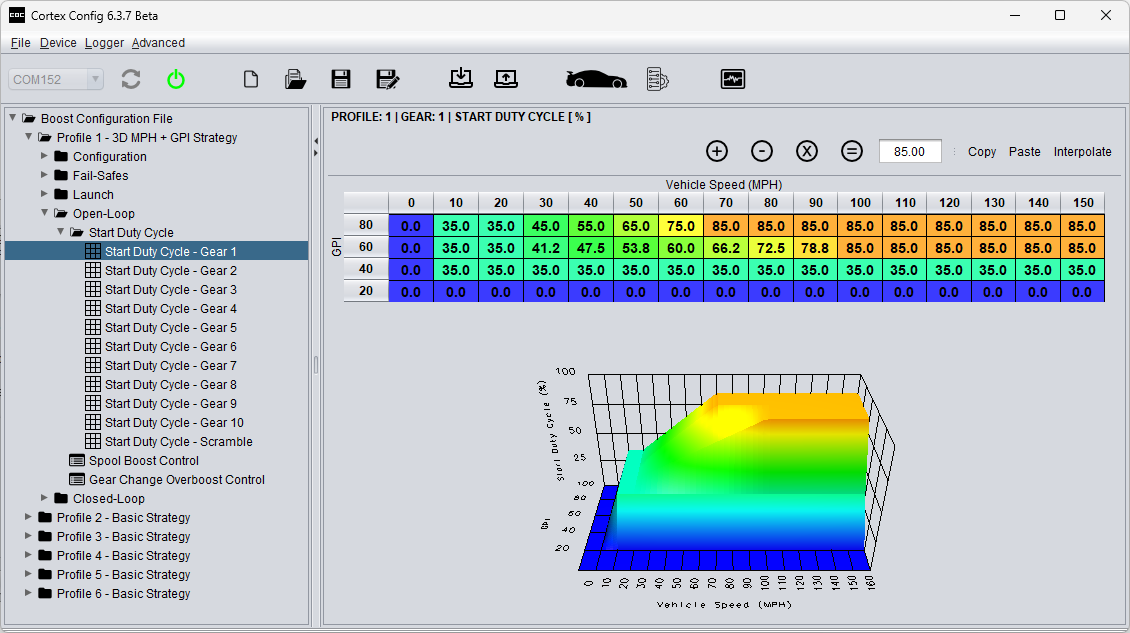

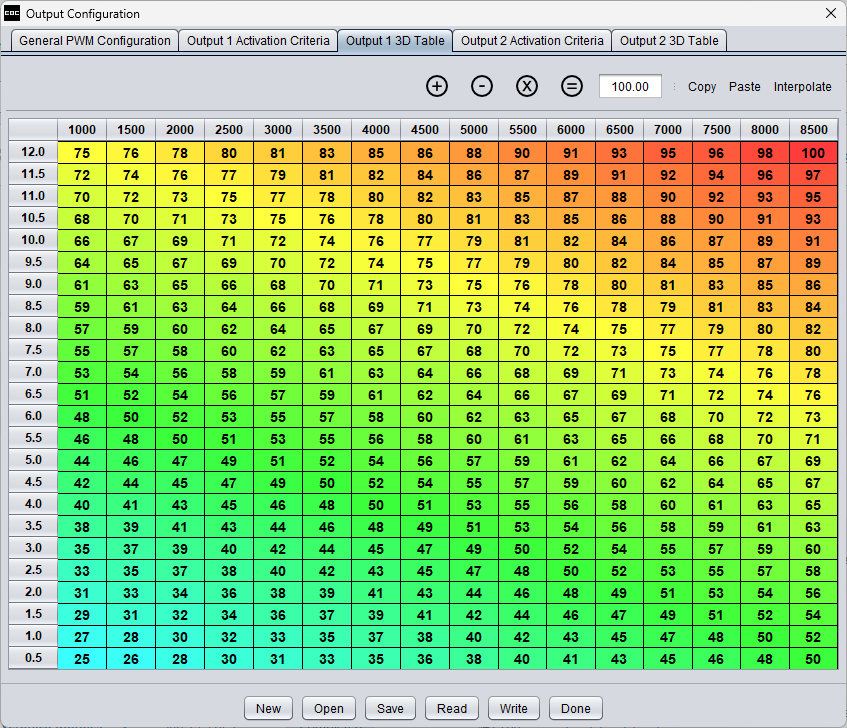

The most advanced option, featuring 64-cell 3D tables (16 columns × 4 rows) per gear for duty cycle and target boost. The X-axis can reference RPM or speed, while the Y-axis is driven by a sensor connected to the general-purpose input—commonly throttle position or ethanol content—for highly adaptive, precision boost control.

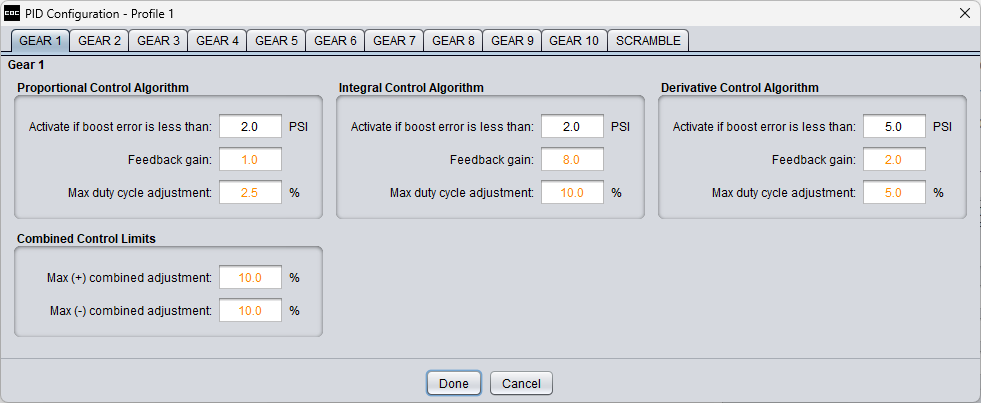

Closed-Loop PID Control

The Cortex EBC employs a highly tunable PID (Proportional-Integral-Derivative) closed-loop control algorithm designed for precise, stable boost regulation. Per-gear PID tuning allows feedback response to be optimized for changing load, traction, and turbo dynamics across the powerband.

Fine-tune closed-loop behavior with full control over:

- Activation threshold for P, I, and D relative to target boost

- Individual gain for each P, I, and D component

- Maximum correction authority for each P, I, and D term

- Maximum combined correction applied by the PID algorithm

Boost Scramble Control

Instantly increase boost, decrease boost, or completely disable boost control at the push of a button. Boost scramble can be activated using the top button on the Cortex EBC display or by wiring an external button to one of the three available inputs on the Cortex EBC wiring harness. Scramble override settings are available for all open-loop and closed-loop control parameters.

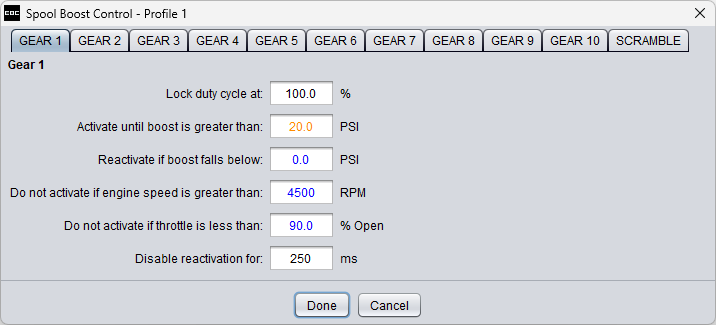

Spool Boost Control

Reach full boost as quickly as possible by applying a high static duty cycle until a target boost level is achieved. Particularly beneficial for large-frame turbochargers. Advanced activation criteria prevent spool control from engaging in conditions that could cause overboost, such as immediate respooling after a high-RPM shift.

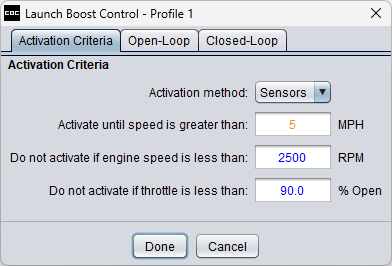

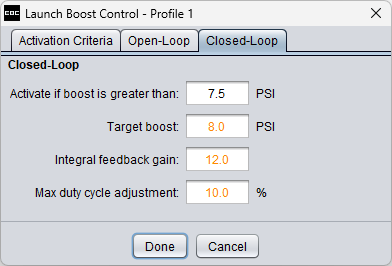

Launch Boost Control

Override normal boost control during a launch to optimize standing-start acceleration and repeatability. Launch boost control can be activated using sensor-based conditions—such as vehicle speed (MPH), engine speed (RPM), or throttle position—or by wiring an external button to one of the three available inputs on the Cortex EBC wiring harness.

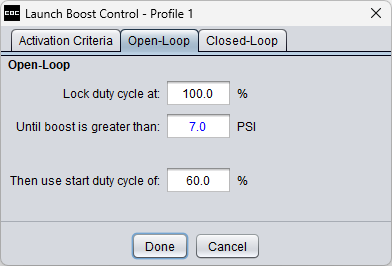

A multi-stage control strategy allows the duty cycle to be initially locked at a high value to build boost as quickly as possible, then reduced to achieve your target launch boost level. An optional simplified closed-loop control mode can be enabled to improve boost consistency from pass to pass. Ideal for drag racing or any application where repeatable launches matter.

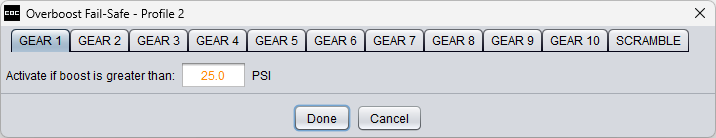

Boost Control Fail-Safes

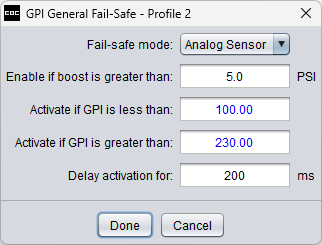

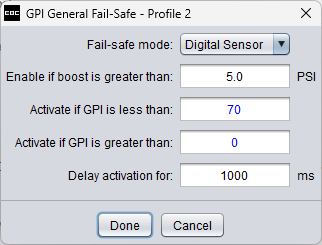

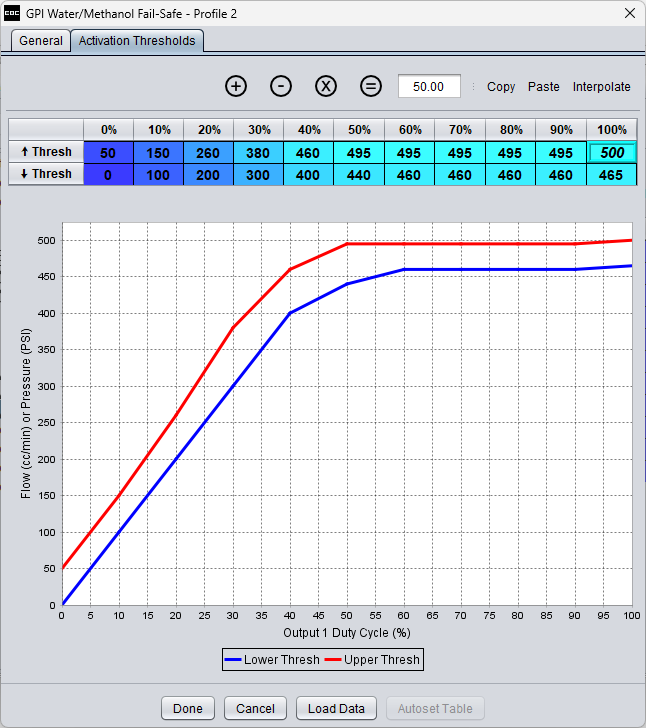

The Cortex EBC features three independent, configurable fail-safe systems that automatically disable boost control to help protect your engine. Fail-safe activation can be triggered by overboost conditions or abnormal readings from any sensor connected to the general-purpose input (GPI). Common applications include monitoring air-fuel ratio, ethanol content, turbo speed, and water/methanol pressure or flow.

The GPI general fail-safe allows boost control to be disabled based on sensor data connected to the general-purpose input (GPI). The fail-safe can be configured to activate if the sensor value falls below a user-defined threshold, exceeds a specified limit, or operates outside of a defined range. An adjustable delay can be applied to prevent unintended activation due to momentary or erroneous sensor readings.

INTELLIGENT GEAR DETECTION

Effective gear-based boost control depends on accurate gear detection. Rather than relying on external switches or hard-wired inputs, the Cortex EBC continuously analyzes the relationship between engine speed and vehicle speed to determine the active gear in real time. This allows the system to quickly and accurately detect upshifts, downshifts, and skipped gears, ensuring the correct boost control strategy is always applied.

- Precise gear-based boost control for street, drag racing, and road-course applications

- Near-instantaneous gear change detection

- Supports transmissions with up to 10 speeds

- Compatible with manual, dual-clutch (DCT), and most automatic transmissions

HIGH-SPEED DATA LOGGING

The Cortex Config software includes a built-in high-speed data logger that allows you to capture and review real-time data from the Cortex EBC. With access to 32 logging parameters—including boost pressure, engine speed (RPM), vehicle speed, solenoid duty cycle, closed-loop target boost, closed-loop duty-cycle corrections, and auxiliary output duty cycles—you can quickly analyze system behavior and make precise control adjustments with confidence.

An internal logging feature is also available, allowing data to be recorded directly on the Cortex EBC without requiring a laptop in the vehicle. Logging is automatically triggered by boost pressure and stops after 500 samples are collected, providing approximately 20 seconds of data at a 25 Hz boost control solenoid frequency.

THREE SENSOR INPUTS

RPM

Primary Function:

Engine Speed Input

Alternate Functions:

Launch Boost Control Activation

Boost Scramble Control Activation

Transbrake Bump Activation

SPEED

Primary Function:

Vehicle Speed Input

Alternate Functions:

Launch Boost Control Activation

Boost Scramble Control Activation

Transbrake Bump Activation

GENERAL-PURPOSE

Primary Function:

Additional sensor input (analog or digital) for boost and output control mapping.

Alternate Functions:

Launch Boost Control Activation

Boost Scramble Control Activation

Transbrake Bump Activation

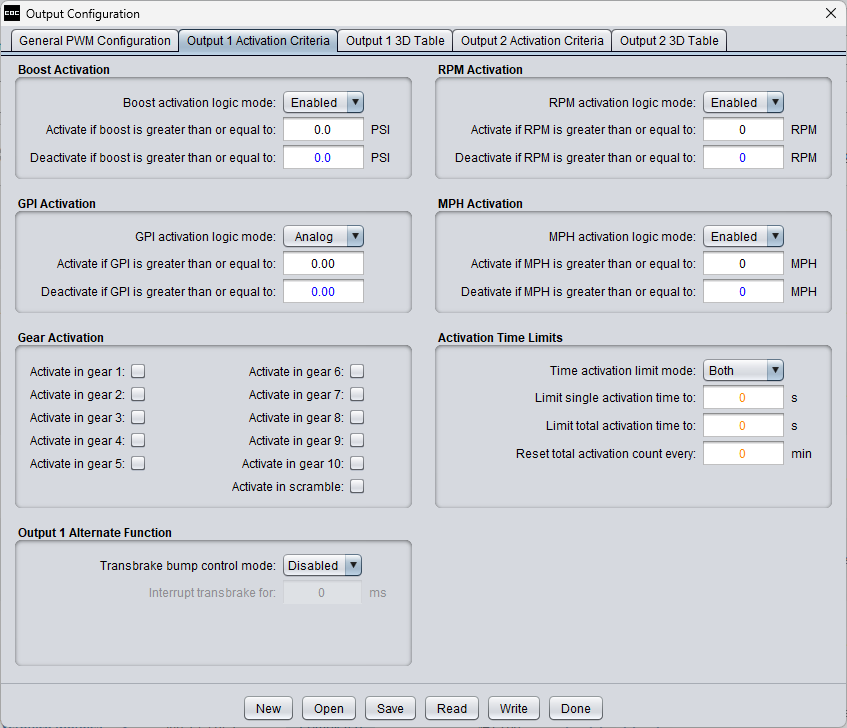

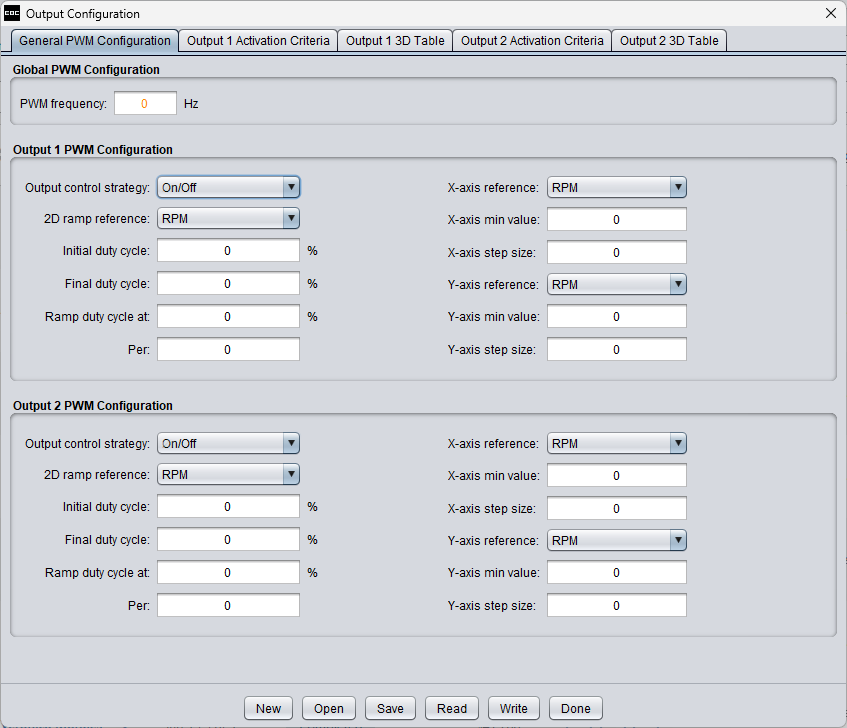

TWO AUXILIARY PWM OUTPUTS

Add intelligent activation and progressive control to pumps, solenoids, and other accessories. Common applications include water/methanol injection, nitrous injection, secondary fuel pumps, intercooler pumps or sprayers, shift lights (single or dual stage), and even transbrake bump control. Each output can be configured independently and activated based on boost pressure, engine speed (RPM), vehicle speed, or any sensor connected to the Cortex EBC’s general-purpose input. Flexible mapping options support simple on/off control, 2D progressive control, or full 3D progressive control.

The auxiliary PWM outputs can directly drive resistive loads drawing up to 200 mA. External drivers or relays are required for solenoids, pumps, and other high-current devices.

RELATED PRODUCTS

DIODE PROTECTED RELAY • LOW AMP SOLENOID DRIVER • HIGH AMP SOLENOID DRIVER • WATER/METHANOL INJECTION PUMP DRIVER

COMPLETE BOOST AND WATER/METHANOL CONTROL SOLUTION

While the Cortex EBC is best known for its advanced boost control capabilities, it also functions as a powerful water/methanol injection (WMI) controller. Its 2D and 3D duty-cycle mapping capabilities are ideally suited for progressive WMI control, with additional WMI-specific features that create a truly integrated turbo boost and water/methanol control solution.

By adding a water/methanol flow or pressure sensor, the Cortex EBC can actively monitor WMI system performance. This data can be used to fine-tune injection settings and automatically disable boost control in the event of an injection system malfunction or failure. With the Cortex EBC, there is no need for a separate WMI fail-safe controller—simply connect a flow or pressure sensor to the general-purpose input to gain both WMI control and fail-safe protection from a single device.

To simplify system setup and maintenance, the Cortex EBC includes a built-in WMI Priming feature. This allows the WMI outputs to be manually activated at 100% duty cycle using the top button on the controller’s display, making it easy to purge air from the system or check for leaks.

TECH SPECS

Engine speed signals compatible with the Cortex EBC are typically available in the factory wiring for most applications. However, older vehicles may require additional hardware to convert a VR sensor signal into a waveform that the Cortex EBC can detect.

The following engine speed signal types can be connected to the Cortex EBC (in order of preference):

- Tach signal from ECU/ECM/PCM or gauge cluster

- RPM output from CAN Bus Wheel Speed and RPM Interface for Mustang / F-150

- RPM output from CB-2 CAN Bus Speed and RPM Interface

- Cam or crank position sensor

- The Cortex EBC can interpret any trigger wheel pattern with 60 teeth or less (tooth gaps will not cause any issues).

- All 3-wire Hall sensors can be connected to the controller. An external pull-up resistor may be required if the sensor is connected to the Cortex EBC only.

- Some 2-wire VR sensors can be connected directly to the controller without any additional hardware, but using a VR sensor interface such as the Speed Sensor Adapter V2 or VR To Hall Sensor Converter is strongly recommended.

- Ignition coil trigger signal from ECU/ECM/PCM or ground (-) terminal on the primary (low voltage) side of an ignition coil

- Electrical noise on some applications may prevent the Cortex EBC from accurately calculating RPM.

- Port fuel injector trigger signal from ECU/ECM/PCM (not compatible with gasoline direct injection)

- Electrical noise on some applications may prevent the Cortex EBC from accurately calculating RPM.

The Cortex EBC is compatible with vehicle speed signals that generate up to 192,000 pulses per mile. In most vehicles manufactured between 1988 and 2007, compatible signals can typically be found at the transmission, differential, ECU/ECM/PCM, or gauge cluster. However, older vehicles may require additional hardware to convert a VR sensor signal into a waveform that the Cortex EBC can detect.

For many vehicles manufactured after 2007, additional hardware is necessary to extract a vehicle speed signal from the CAN bus system or an ABS wheel speed sensor.

For optimal performance in boost-by-speed applications, the vehicle speed signal should come from an “undriven” source, e.g., the front wheels on a rear-wheel-drive (RWD) vehicle or the rear wheels on a front-wheel-drive (FWD) vehicle.

The following vehicle speed signal types can be connected to the Cortex EBC:

- Speed pulse output from ECU/ECM/PCM or gauge cluster

- Speed pulse output from CAN Bus Wheel Speed and RPM Interface for Mustang / F-150

- Speed pulse output from CB-2 CAN Bus Speed and RPM Interface

- Transmission output shaft speed sensor or differential speed sensor

- All 3-wire Hall sensors can be connected to the controller. An external pull-up resistor may be required if the sensor is connected to the Cortex EBC only.

- Some 2-wire VR sensors can be connected directly to the controller without any additional hardware, but using a VR sensor interface such as the Speed Sensor Adapter V2 or VR To Hall Sensor Converter is strongly recommended.

- Wheel speed sensors

- Active (2-wire Hall) ABS wheel speed sensors require the use of the Speed Sensor Adapter V2. Most active sensors are compatible with this device. 2011+ Ford Mustang and F-150 applications can alternatively use the Wheel Speed Sensor Adapter for Mustang / F-150.

- Some passive (VR) ABS wheel speed sensors can be connected directly to the controller without any additional hardware, but using a VR sensor interface such as the Speed Sensor Adapter V2 or VR To Hall Sensor Converter is strongly recommended.

- If you have installed an aftermarket 3-wire Hall sensor to read wheel speed, no additional modules are required, but your sensor may require an external “pull-up resistor” to generate a signal. Consult your sensor manufacturer for more information.

The general-purpose input is compatible with a wide range of analog (voltage) and digital (frequency) sensors that provide a linear output. A linear output means that when you plot the raw sensor output (volts or Hz) against the scaled sensor output, the result is a straight line, as illustrated in the chart below.

The general-purpose input can be used for various applications, such as monitoring throttle position, ethanol content, air-fuel ratio from a WBO2 controller, turbo speed, or water/methanol injection pressure or flow. Most temperature sensors produce a nonlinear output and cannot be interpreted by the Cortex EBC.

Min Voltage: 0 V

Max Voltage: 16 V

Max Frequency: 5,000 Hz

Logic Threshold: 2.5 V

Linear Sensor Output Example

Gear detection requires both engine speed (RPM) and vehicle speed signals. For accurate gear detection, the vehicle speed signal must be sourced from a location directly connected to the drivetrain; wheel speed sensors on non-driven wheels (such as a front wheel speed sensor on a rear-wheel-drive vehicle) cannot be used.

The Cortex EBC was engineered for universal applications and is compatible with nearly any electronically fuel-injected vehicle. From single-turbo four-cylinder engines to twin-turbo ten-cylinder platforms, turbodiesels, and everything in between, customers around the world rely on the Cortex EBC for precise boost control.

Some applications may require additional electronic modules. If you have questions about compatibility with your specific vehicle, contact us at [email protected] and we’ll be happy to help.